Sandtinel just works better.

Sandtinel Sand Separators are setting the standard for sand separation with trailblazing solutions for multiple applications that are simple to set up, operate and monitor. Boost productivity, eliminate downtime, reduce fugitive emissions, and lower overhead costs, all while minimizing your operational footprint.

The Sandtinel’s fleet provides superior separation efficiency, high storage capacity, better turndown performance, and overall, more effectively manages produced sand compared to traditional options.

For specific well conditions, Sandtinel offers CFD simulations, performance estimates, emissions comparisons, and more upon request. Advanced units and configurations are also available to tackle more challenging conditions.

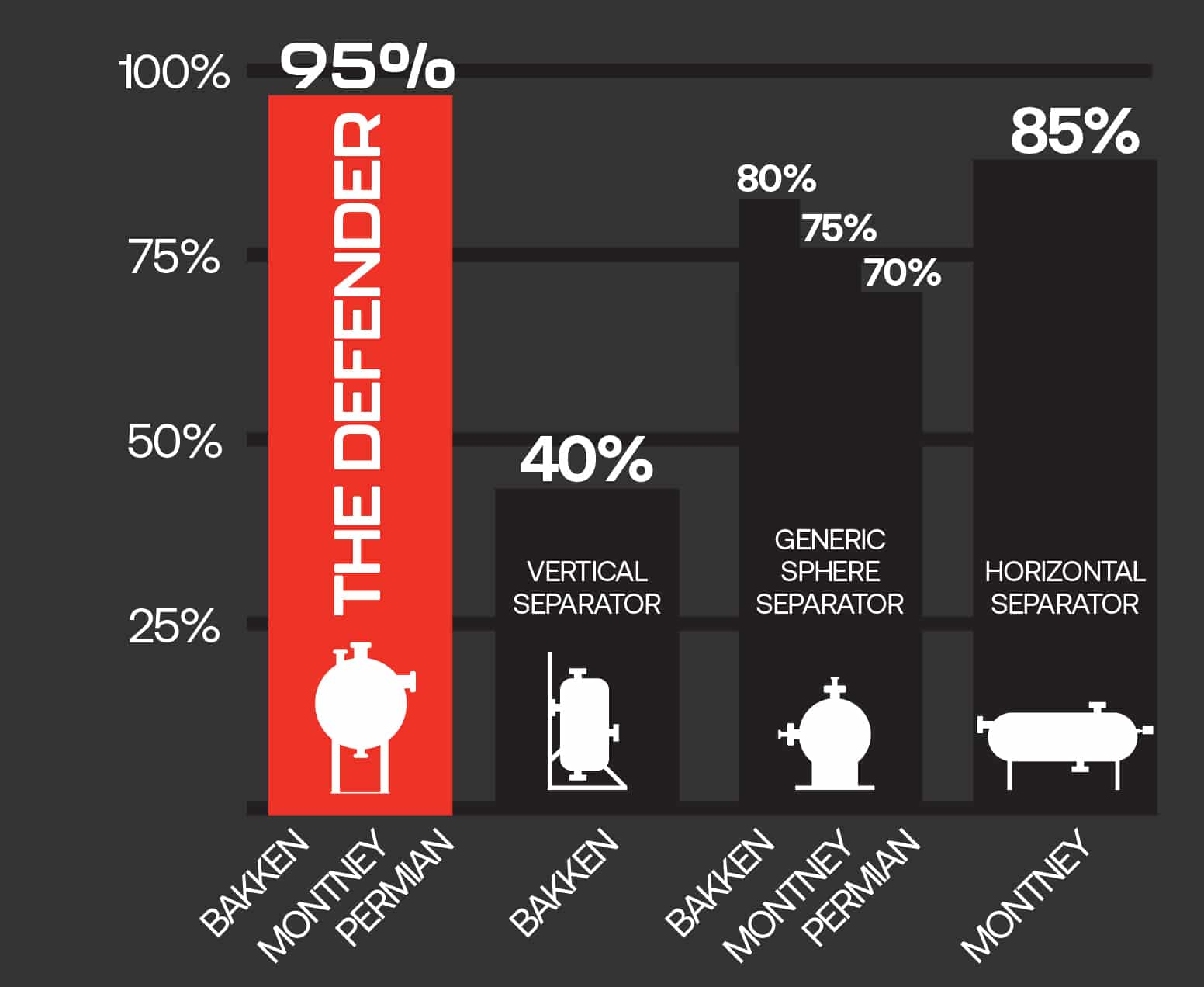

Producers have learned that not all sand separators are equal. Advanced Computer Fluid Simulations (CFD) as well as field trials across major basins show that Sandtinel's Vapor Lock technology and high-performance separation efficiency consistently outperforms alternative technologies and imitators.

The Sandtinel Advantage

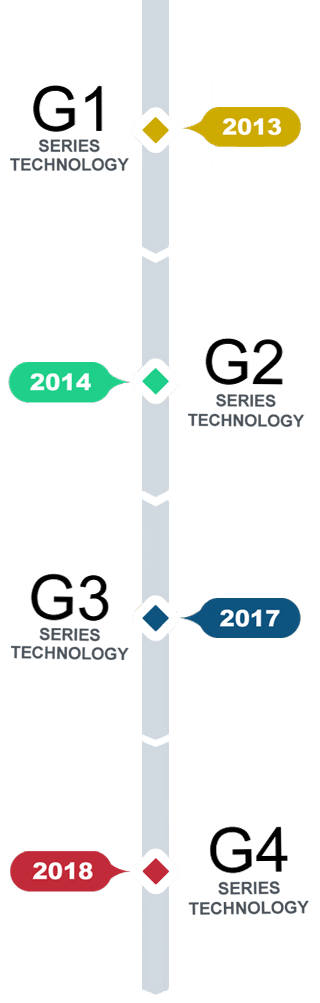

And ahead of constantly evolving operations with Sandtinel's superior technology, unrivaled performance, and sand control solutions that are always on the cutting edge of what's possible.

Our Approach.

The transformative power of technology and design drives our team of R&D experts to relentlessly innovate, test, and search for pragmatic solutions that simplify products, elevate performance, and inspire change.

We accomplish this by:

The VL-TEK™’s 95%+ sand capture rate is undisputed & unrivaled in the industry.

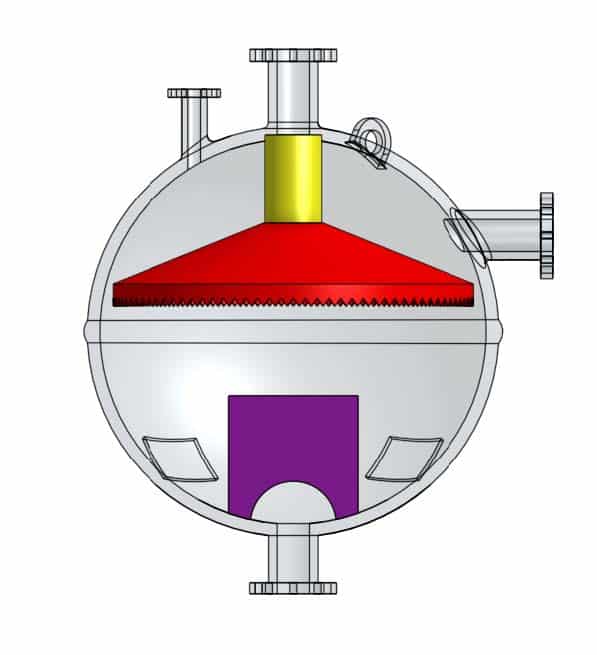

Found at the core of every vessel, Sandtinel's VL-TEK™ technology is fundamental to each generation’s design, resulting in superior separators that continue to outperform competing separators in all measurable categories, greatly lowering overall OPEX.

In the upper hemisphere, a large cross-sectional saw-tooth dome creates a vapor lock and temporarily forces a phase separation of the gas from the liquids in the incoming mixture.

The lower hemisphere consists of a cross-shaped vortex breaker and anchor plate designed to capture and lock in sand at the bottom of the vessel for effective removal and monitoring.

Monitor sand weight in real time with the SMS.

The Sand Measurement System (SMS) utilizes calibrated load cells to accurately measure the amount of sand collected by the separator on each dump providing a complete view allowing field personnel to be more efficient and proactive with drain cycles.

Load cells under the vessel legs can measure the amount of sand collected in the separator.

Monitor sand weight in real time allowing field personnel to be more efficient & proactive with sand drain cycles.

The Sandtinel Dispatcher is an optional automated dump solution add-on which is fully integrated with the Sandtinel system and can be operated on a timed basis or connected to SMS.

"*" indicates required fields

There are hundreds of Sandtinel units in use across North America, and we're here to support your operations in any basin with offices in:

This website is owned, operated, and maintained by Sandtinel, referred to as "this website" in the following document.

This website respects the privacy of our employees, our suppliers and our clients and ensures that the personal information we collect remains secure and protected. There are times where personal information must be shared with an interested third party. In such circumstances, this website will not release any personal information without first advising of its intended use and obtaining the permission to do so from the affected individual.

We do not automatically gather any personal information from you, such as your name, phone number, email, or address. This information is only obtained if you supply it voluntarily, usually through contacting us via email or registering in a secure portion of the site. By choosing to provide us with your Personal Information, you are consenting to its use in accordance with the principles outlined in this Privacy Policy and as outlined at the time you are asked to provide any Personal Information.

Any personal information you do provide is managed according to the Alberta Freedom of Information and Protection of Privacy Act. This means that, at the point of collection, you will be informed that your personal information is being collected, the purpose for which it is being collected and that you have a right of access to the information.

Our policy is designed to meet or exceed the requirements of Canadian Federal and Provincial privacy laws. We constantly self-evaluate our practices and procedures to maintain the highest standard in this regard.

This website will make every effort to ensure personal information remains current and is updated internally and with third party suppliers in a timely manner. Individuals are expected to update this website with any changes to their personal information. The information will only be updated when required for the intended, previously described purposes.

Only employees who need the information to perform a specific job have access to personal information.

We have secure databases where we store data. We also may store your personal information in paper document files in our offices.

The processes of our business include sharing your personal information with others to carry out our placement services.

Email transmission can be accessed by other Internet users. If you want to keep certain information confidential you may contact us by telephone, in person, or via mail.

This website has set mandatory retention time limits based on Provincial Employment and Labour Standards and third-party suppliers are instructed to follow the same guidelines. Appropriate safeguards relevant to the sensitivity of the information will be employed.

This website will use your Personal Information to contact you for support purposes. If you wish to be removed from our contact database, please info@energera.com.

Like most web servers on the Internet, this website' servers maintain access logs that record web browser activity. These logs associate an Internet Protocol (IP) address with each request for content from the servers.

When you visit this web site, our web server automatically collects a limited amount of standard information essential to the operation and evaluation of the web site. This information includes:

This information helps us assess our information services and is used only for this purpose. It is collected in compliance with section 33 of the Freedom of Information and Protection of Privacy (FOIP) Act.

This information is collected in order to help make our site more useful to visitors, to learn about the number of visitors to our site, and to learn about the types of technology our visitors use. We do not track information about individuals and their visit. We will not identify users or their browsing activities, except as required by a law of Alberta or Canada or if we are compelled to produce this information for a legal proceeding.

For security purposes and to ensure that this service remains available to all users, this computer system employs software programs to monitor network traffic to identify unauthorized attempts to upload or change information, or otherwise cause damage.

Except for authorized law enforcement investigations, no other attempts are made to identify individual users or their usage habits.

Our web servers are able to use "cookie" technology to keep track of the web browsers with which they are communicating.

During a cookie transaction, a web server will hand a web browser some data prescribed by the web site's developers. The web browser will return that data with its next request for content

from the web site. Using this technology, it is possible for an application running on a web server to distinguish one web browser's activity from another.

This website' web servers will make use of such cookies when required to identify ongoing sessions with individual online visitors. Examples include:

In all cases, the cookie data this website' web servers may hand your browser contain only "session" identifying information. No other personal information is passed to your browser, where it may be stored on your own computer.

Cookie-related data is not permanently stored on this website' web servers. Information stored temporarily in our cookie collection never includes a visitor's name or address or sensitive data.

Further, this website does not match for its records any session-identifying cookie information with the Internet Protocol (IP) addresses described above in the information on monitoring Web-Site Traffic.

This website is committed to the security of personal information it may collect online or offline. This website has taken reasonable precautions to protect this personal information from loss, misuse or alteration. Any third parties who may have roles in managing such information on behalf of the this website are also committed to the same principles.

This website includes links to web pages or sites operated by third parties. We endeavor to make it clear that certain links will take you away from our site and to destinations over which we have no control.

Our public website privacy statement does not apply to the sites of third parties to which we link. Instead, we encourage you to review the policies of these sites yourself upon your arrival.

This website will release your personal information to you upon request, along with the use and disclosure of any personal information.

Specific requests for information can be directed to the Privacy Officer via info@energera.com. The information will be released within 30 days of receipt of the request. Should this website not be able to comply with the request, a justifiable reason will be given to the requestor. This website considers the following reasons justifiable reasons to refuse access to personal information.

This list is not exhaustive and other reasons may be considered justifiable.

You have the right to file a challenge about this website's compliance with Privacy legislation. This website will consider all requests seriously and will investigate any complaints thoroughly. To make a challenge please send all relevant details and specifics to this website's Privacy officer at info@energera.com.

This website will occasionally update this privacy statement. When we do, we will also revise the "last updated" date at the top of the privacy statement. For material changes to this statement, this website will notify you by placing prominent notice on the website.

For questions or comments regarding this public website privacy statement please contact us by email: info@energera.com.